- Reel To Reel Stamping

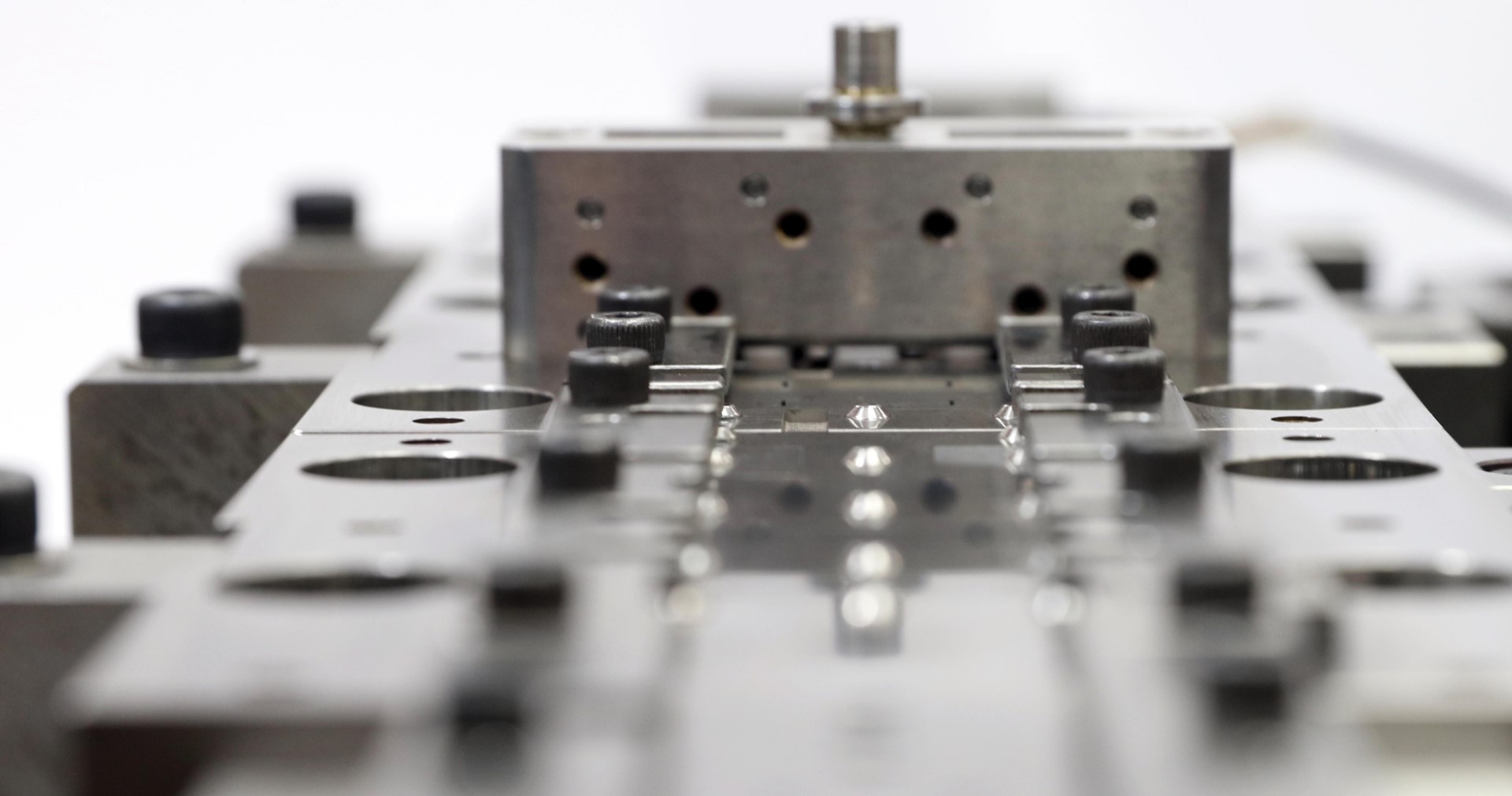

- Tooling

Engineered for performance and durability, so you experience maximum value from your investment

At the core of Batten & Allen's manufacturing expertise is our precision tooling, meticulously designed and built on-site. Our state-of-the-art toolroom allows us to create highly accurate tools, tailored to our customers' unique specifications. This fully equipped in-house resource empowers us to provide a rapid response to client needs, defined by unparalleled quality control.

Standardising Innovation in Tool Design

Crafted in-house to your exact specifications, ensuring faster turnaround, simple integration and enhanced quality control. By implementing a standard modular tool format, we've standardised our designs—resulting in significantly reduced lead times and enhanced consistency across products. This modular system allows for rapid scaling and adaptability, ensuring that our tooling solutions meet the dynamic needs of you and your industry.

Seamless Tooling Transfers

Stuck with an underperforming supplier? We make tooling transfers easy, reducing disruption while improving the reliability and efficiency of your project. Our expert team is equipped to handle complex transitions, guaranteeing increased reliability and minimal disruption – so you can transfer your business to a more effective partner, quickly.

Tooling Design: Reliability, from Prototype to Production.

Discover the advantages of our standard modular tool format.

We pride ourselves in our ability to serve these market sectors with various components supplied from bespoke tooling including…

Lead Frames

We produce multi impression fine tolerance lead frames for the Electronics market. Producing multiple tooling up to 32 impression gives us the ability to produce millions of parts at a low unit price. We can offer pre plated, post or selective plating on these frames.

Connectors

With our in house design facility we can assist our customers in the most suitable offer a varied selection of connectors to suit all markets. With the compliment of our own plating lines and our support to customers with assembly tooling we can offer a complete solution.

Press-fit Pins

With a history of manufacturing compliant pin components we fully understand the technical requirements of this product. We can supply from standard or high performance alloys in different thicknesses and working with our customers we can undertake new designs to overcome current challenges.

IDC’s

Fine tolerance Insulation Displacement Connectors can be manufactured in a variety of materials and plating finishes on a close pitch design with carrier bars for fast automated assembly.

Custom Precision Stamping

Precision stamping and assembly, with 0.010mm thin strip up to 2mm, and material including;

- Numerous Copper alloys

- Nickel Iron alloys

- Stainless steel

- Pre plate and post plate applications

The Perfect Partnership

Our in-house tooling ensures unmatched precision, repeatability and longevity, delivering consistent high-quality stamped components at scale.

Partnership with Batten & Allen is rooted in a shared dedication to precision, quality, and collaborative approach. Typically from sectors such as automotive, aerospace, or electronics, they resonate with Batten and Allen's ethos of providing customised tooling solutions, tailored to meet the distinctive requirements of each project. Such a partner values a coherent and structured purchasing process, ensuring seamless communication and strict adherence to compliance and quality standards.

Precision Tooling

Batten & Allen are experts in precision tooling, ensuring each part is crafted to meet exact specifications and standards. Our expertise translates into high-performance tools for high performance jobs.

Bespoke Tooling Solutions

Tailoring tooling solutions to match the unique requirements of each project is a hallmark of Batten & Allen's service. This approach guarantees not only functionality but also cost-effectiveness.

Quality Checking

The stringent quality control measures at Batten & Allen ensure that every tool meets the highest industry standards. Clients can trust the consistency and longevity.

Reliability

Batten & Allen prioritise punctual delivery times. Their dedication to meeting deadlines underscores the dependable partnership clients can expect when engaging with us for tooling services

Seamless Assembly

Smooth, uninterrupted, and efficient Our assembly systems create a continuous production process, Fast, accurate and totally reliable

Cost-Efficiency

Through optimised operations and economies of scale, we offer cost-effective tooling solutions without compromising on quality. Clients benefit from competitive pricing, knowing that at Batten & Allen we NEVER compromise on quality.

Case Study

Precision tooling excellence: from prototype to production

Dive into Batten and Allen's journey of mastering tooling design, ensuring reliability at every stage. Our in-house capabilities, from advanced wire erosion to state-of-the-art machining centers, showcase our commitment to delivering high-quality components efficiently.

Learn how our meticulous design process, combined with our expertise in stamping and plating, offers unparalleled precision and cost-effectiveness.

News and insights

Everything about the market, Batten and Allen and the services we offer to give you the competitive edge.

2 min read

New ‘Tube Map’ Online Resource For Stamped/Plated Components

Batten & Allen: Aug 29, 2025

Infographic: Batten & Allen's Turnkey Process From Concept to Delivery

Batten & Allen: Jan 13, 2025

Tooling Reliability

Batten & Allen: In-house precision tooling and state-of-the-art toolroom expertise. Questions about our services? We're here to help.