Batten & Allen Providing Power Module Lead Frame Manufacture from Start to Finish

Lead frames are one of the foundations behind electronic components and ensuring their reliability and quality is essential for any component. What...

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

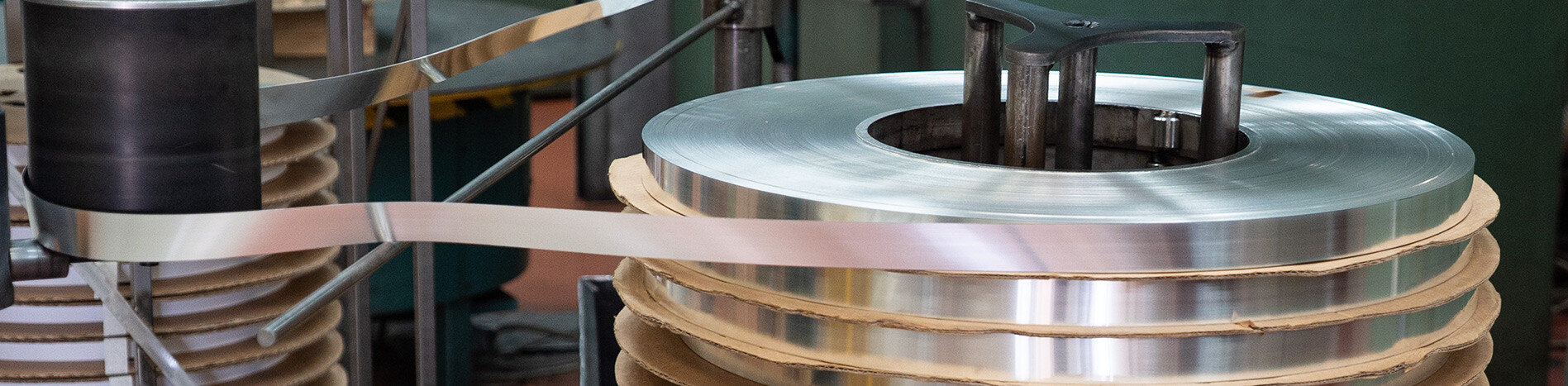

When sourcing a new precision stamped component, both the stamping process and new tool design are key to ensuring production of a highly consistent, high-quality component and an efficient output that meets both technical needs and productivity targets.

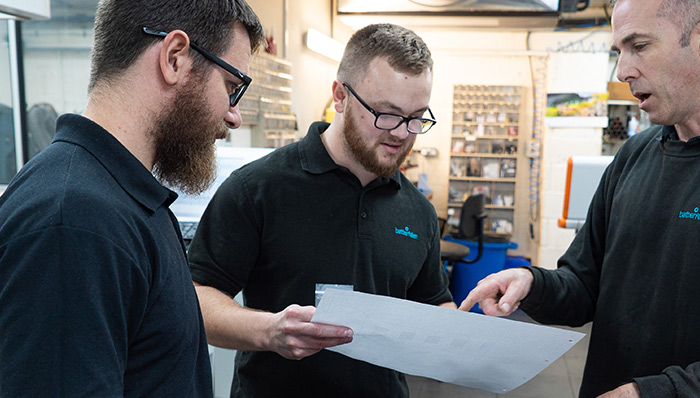

The Batten & Allen design process can include creating the best tool to suit a specific product that is already fully specified or assisting from the very start of the project to help in the initial concept and final design of the component to best suit established tooling and production process optimisation. The ability to provide a service for all of these in-house means Batten & Allen can help from any of the following stages in the component production process:

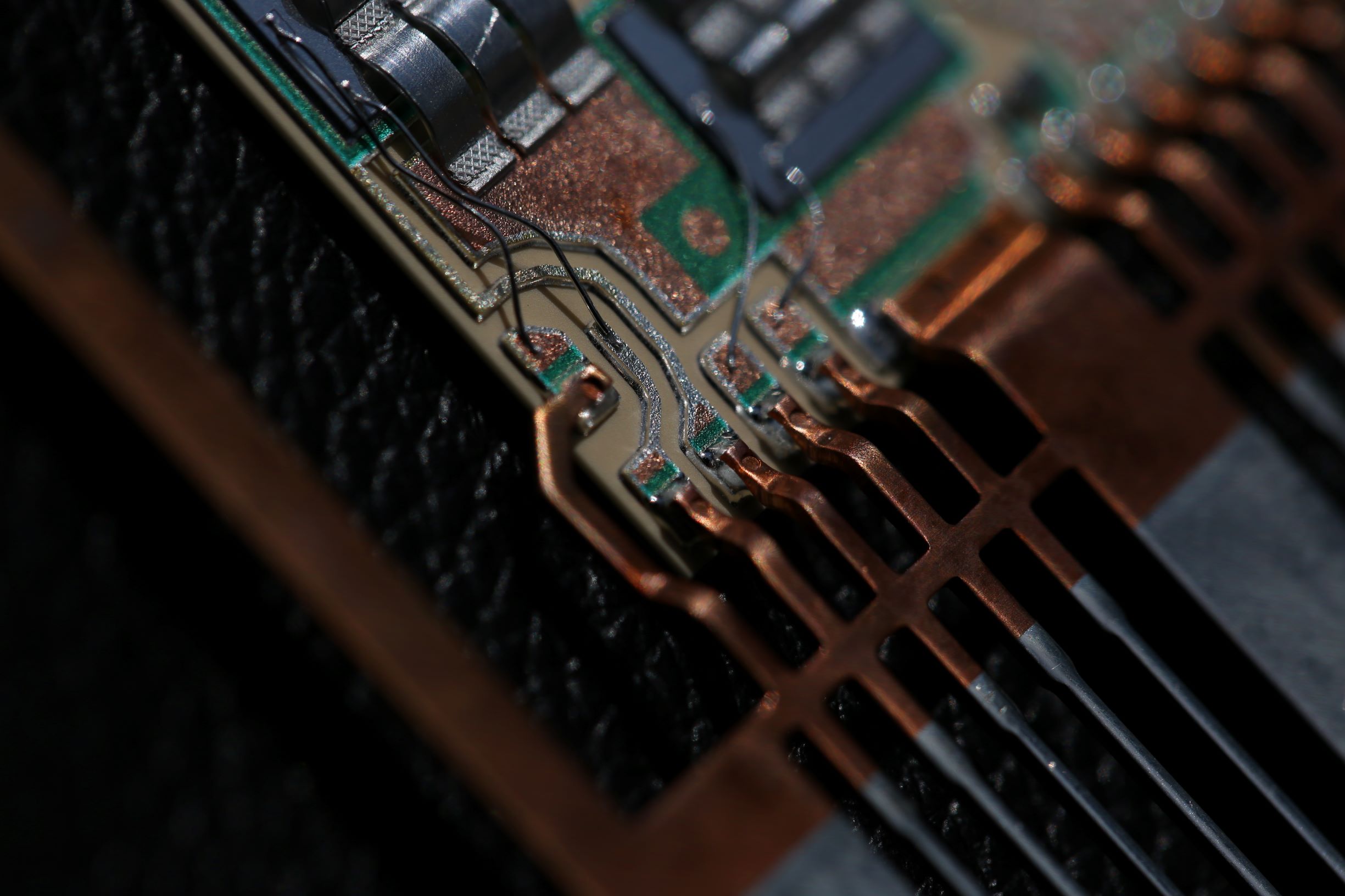

One area of electronics that is becoming popular is the use of power modules, and factors such as high-efficiency and high-quality are of utmost importance. The pressure for high-quality parts is further compounded with the demands from the automotive sector for productivity and ‘production quality’ parts throughout the whole testing process. Due to these demands, a world leading electronics component manufacturer / supplier came to Batten & Allen to develop a range of power module lead frames.

Batten & Allen used their expertise with a wide range of different plating and substrate options, including exotic copper alloys not commonly seen in the industry during the initial stage, to help specify the finished component to both meet functionality requirement but also be ultimately suitable for an efficient, high volume, stamping production process.

Once the component had been specified, Batten & Allen provided initial prototype quantities as low as 1 and as high as 1,000, allowing the customers engineers to evaluate and prototype all downstream production processes before moving onto design validation.

At the design validation stage is where Batten & Allen were able to offer final quality components off quick turnaround tooling for quantities ranging from 1,000 to 50,000, which allowed the customer to prove and develop all the downstream production processes and equipment. This stage ensured the customer could identify hidden faults and protect the large investment for the full power module production line.

Once the design is verified and ready to go into production, Batten & Allen will support the next stage of the process to design the production tooling and process using leading manufacturing methods and technologies for the tooling, stamping, and plating processes. The full process supported under one roof for component and production reliability from start to finish.

Batten & Allen have years of experience in the field of lead frames and plating processes, and are also certified to ISO19001, IATF16949, and ISO14001. This means that every stage of development is managed properly, and a strict set of quality management practices ensures that the final products are to the highest standards.

Having a company take care of its customers to the extent which Batten & Allen go not only saves money, it also saves time. Batten & Allen’s standards ensure that the final product conforms to the most stringent standards (such as RoHS and REACH), are applicable to the designated environments, and will provide reliability for the many years of service that the final product will be operating for.

To discuss a new design and manufacturing project with Batten & Allen Ltd contact our sales team.

Lead frames are one of the foundations behind electronic components and ensuring their reliability and quality is essential for any component. What...

Achieving reliability in metal stamping is a complex challenge that industry leaders tackle through a combination of best practices, technological...

Whether you’re launching a new product or scaling up production, understanding the financial implications is essential to maintain profitability. ...