Tooling Reliability

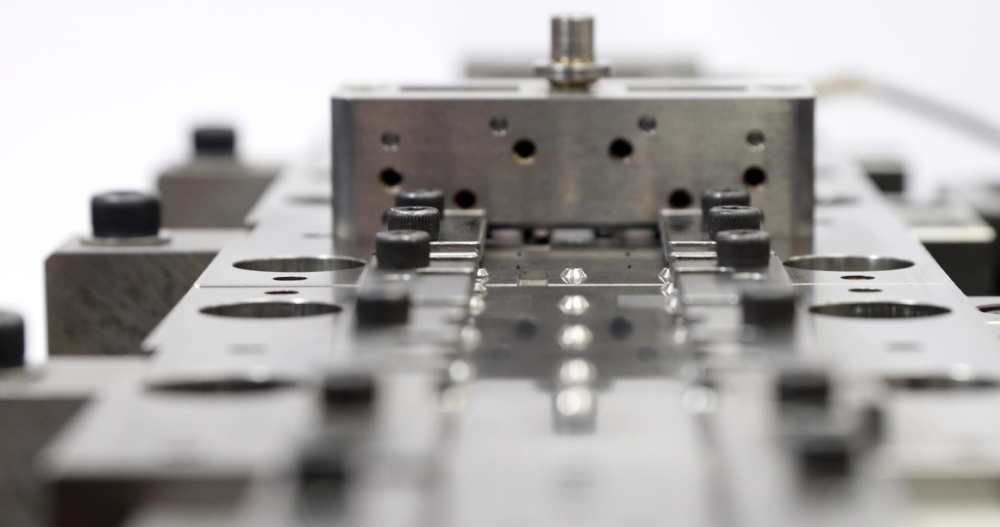

Precision tooling, all designed in-house at Batten & Allen

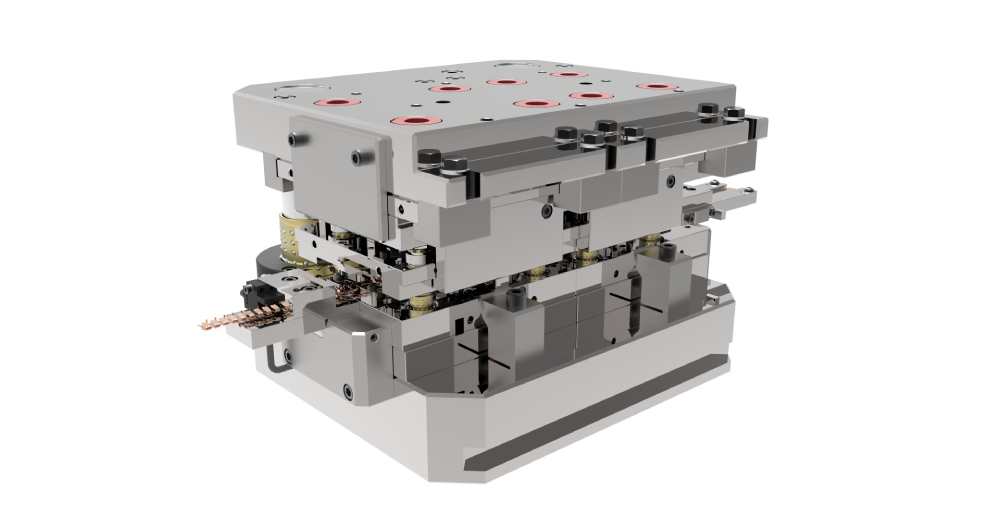

Built to last, our high accuracy, precision tooling is all designed and built in house. With a fully equipped toolroom we manufacture tooling to our customer's unique specification.

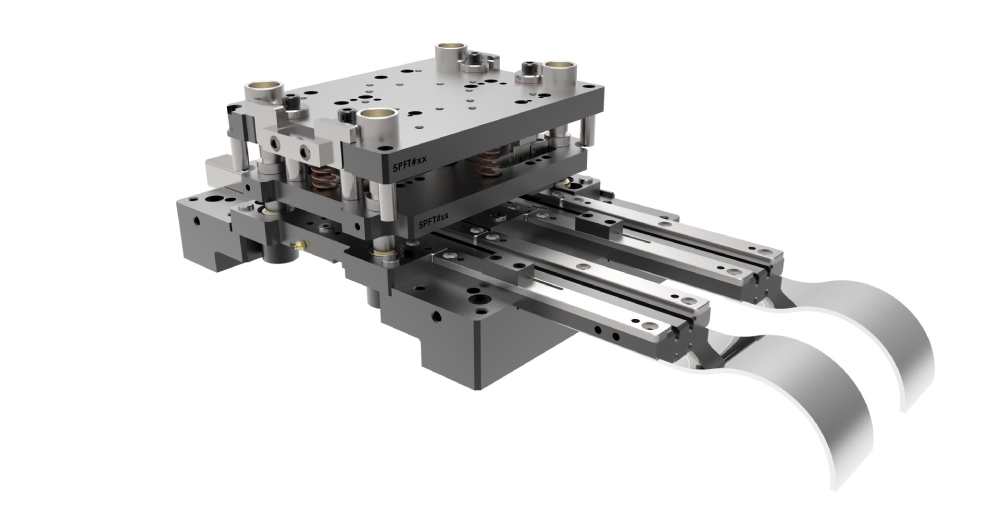

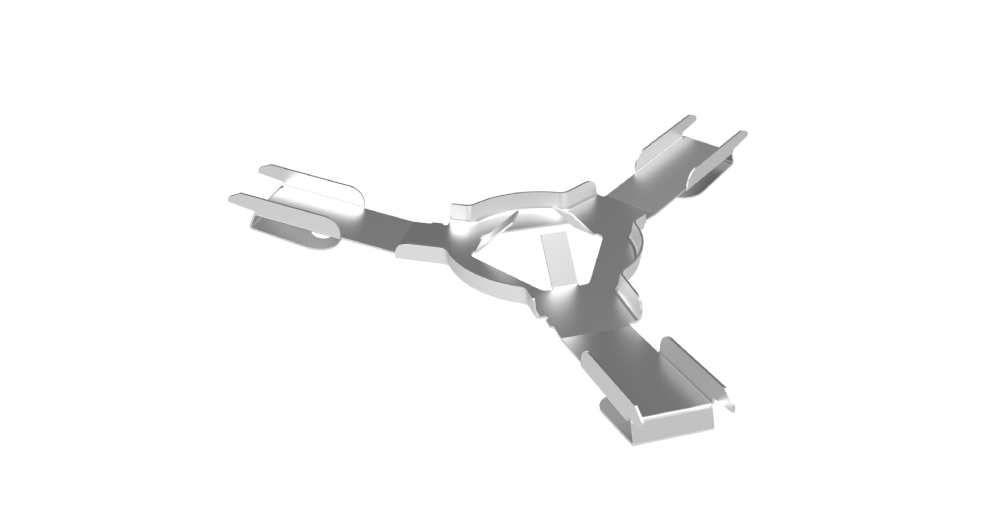

Key to the reliability, accuracy and quality of our tooling is in the design, development and implementation of the standard modular tool format. This allows us to standardise the design resulting in significantly reduced lead times and improved consistency.

We are well equipped to deal with tooling transfers ensuring a reliable changeover and increased reliability.

-

All Batten & Allen tooling is made ‘in-house’

We have a state of the art toolroom with its own design facility that assists customers with prototypes and best material utilisation. We are able to offer high accuracy modular design for high volume and SMED activities, as well as, bespoke ‘standard’ tooling for high accuracy mid volume.

Tool Design:

- Hexagon 3D CAD CAM software from initial concept design through to full tool build and CNC manufacture

- Supported by Auto CAD Stations and Solid Works

Toolroom :- 5 x WEDM

- 2 Agie Charmilles Form 20 EDM

- 2 x high speed EDM Drilling Machine

- 1 Sarix SR-HPM CNC Hole Drilling Machine with 10 Electrode Auto-changer Range 0.17, 0.2, 0.3 & 0.5

- Haas 20 Station Machining Centre

-

Prototype, development and low volume ‘soft’ tooling

Investing in an expensive progression tool without component proving and testing is a daunting prospect for our customers so at Batten & Allen we offer a prototyping service to ease these worries.

We can offer a complete service which includes:

- Wire eroded prototypes

- Etched blanks

- Tool room hand formed parts

- Single impression pressed parts from modular tooling

All of the above offer the customer a low cost fast delivery option of samples for testing before a full production tool is required.

If a more representative sample of the finished part is required we can utilise single impression modular tooling or single cavity mould tools.

At this stage our experienced engineers can offer design and material selection ideas to develop a component that is functional and cost effective.

-

Wire Erosion Facility

We have a state of the art wire erosion facility, which helps keep the press tooling and manufacture of precision stamped parts under one roof for our customers. Having our own dedicated wire erosion facility also helps us to turn around volume metal pressings faster for our customers, with the added benefits of cost saving.

By utilising the benefits of CAD design, allied to wire erosion technology, we achieve an efficient progression between stages of production in the design and development of our tool-making. Working closely with clients in the design and development of their components is part of that process. This helps us to minimise waste in strip design and select the most effective materials.

We have 5 machines including a CUT 1000 machine working to an accuracy of less than 1 micron with the capability to run all machines 24 hours 7 days per week under lights out conditions.

-

Contingency Planning

We have a designated fire proof storage area on site to protect our customer tooling.

-

Tooling Transfers

A tooling transfer usually happens due to poor performance, delivery and quality from an existing supplier. Batten & Allen are well equipped to deal with tooling transfers and ensure a reliable changeover and ultimately increased end product dependability.

Our Tooling Transfer Process

- Submit RFQ – make your tooling transfer enquiry with Batten & Allen;

- Understand detail of the existing tool – this will include providing details of tool dimensions, strip, width and pitch and parts per blow / tool speed, used for the component to guarantee a like-for-like cost comparison;

- Identify existing problems and expected life and volume of the component;

- CAD for component design, previous (last off) samples and quality control records are used to validate the parts can be run on our presses without any issues

- B&A propose any required improvements, maintenance or alterations to the tool;

- Confirm costs;

- Transport of the tool(s) (road, rail, sea, or air);

- Quality and engineering team will liaise with customer engineers and quality department to review proposed changes and increase both quality and efficiency;

- Tool installation (produce trial samples for customer pass off);

- Full Production.

Tooling Design: Reliability, from Prototype to Production.

Discover the advantages of our standard modular tool format.

We pride ourselves in our ability to serve these market sectors with various components supplied from bespoke tooling including…

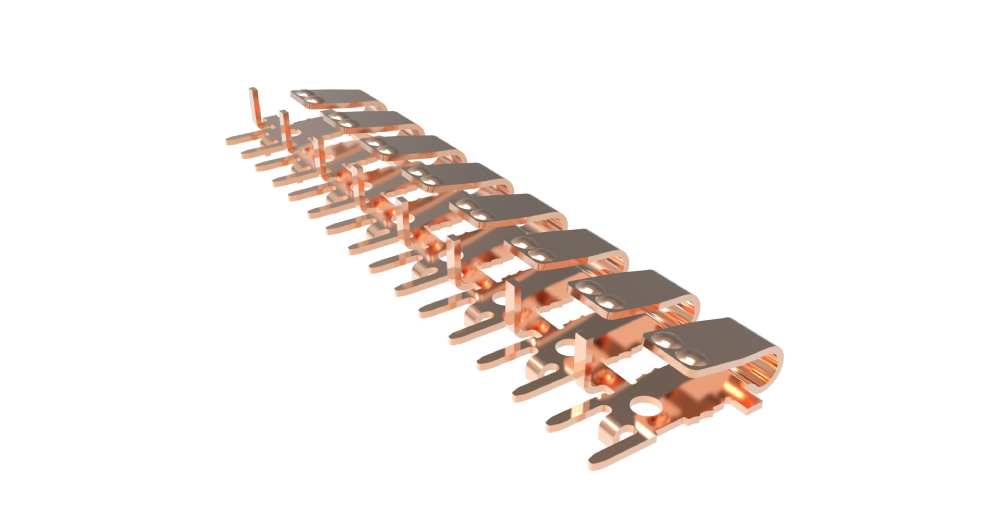

Lead Frames

We produce multi impression fine tolerance lead frames for the Electronics market. Producing multiple tooling up to 32 impression gives us the ability to produce millions of parts at a low unit price. We can offer pre plated, post or selective plating on these frames.

Connectors

With our in house design facility we can assist our customers in the most suitable offer a varied selection of connectors to suit all markets. With the compliment of our own plating lines and our support to customers with assembly tooling we can offer a complete solution.

Press-fit Pins

With a history of manufacturing compliant pin components we fully understand the technical requirements of this product. We can supply from standard or high performance alloys in different thicknesses and working with our customers we can undertake new designs to overcome current challenges.

IDC’s

Fine tolerance Insulation Displacement Connectors can be manufactured in a variety of materials and plating finishes on a close pitch design with carrier bars for fast automated assembly.

Custom Precision Stamping

Precision stamping and assembly, with 0.010mm thin strip up to 2mm, and material including;

- Numerous Copper alloys

- Nickel Iron alloys

- Stainless steel

- Pre plate and post plate applications

The Perfect Partnership

Partnership with Batten & Allen is rooted in a shared dedication to precision, quality, and collaborative approach. Typically from sectors such as automotive, aerospace, or electronics, they resonate with Batten and Allen's ethos of providing customised tooling solutions, tailored to meet the distinctive requirements of each project. Such a partner values a coherent and structured purchasing process, ensuring seamless communication and strict adherence to compliance and quality standards.

Precision Tooling

Batten & Allen are experts in precision tooling, ensuring each part is crafted to meet exact specifications and standards. Our expertise translates into high-performance tools for high performance jobs.

Bespoke Tooling Solutions

Tailoring tooling solutions to match the unique requirements of each project is a hallmark of Batten & Allen's service. This approach guarantees not only functionality but also cost-effectiveness.

Quality Checking

The stringent quality control measures at Batten & Allen ensure that every tool meets the highest industry standards. Clients can trust the consistency and longevity.

Reliability

Batten & Allen prioritise punctual delivery times. Their dedication to meeting deadlines underscores the dependable partnership clients can expect when engaging with us for tooling services

Seamless Assembly

Smooth, uninterrupted, and efficient Our assembly systems create a continuous production process, Fast, accurate and totally reliable

Cost-Efficiency

Through optimised operations and economies of scale, we offer cost-effective tooling solutions without compromising on quality. Clients benefit from competitive pricing, knowing that at Batten & Allen we NEVER compromise on quality.

Case Study

Precision tooling excellence: from prototype to production

Dive into Batten and Allen's journey of mastering tooling design, ensuring reliability at every stage. Our in-house capabilities, from advanced wire erosion to state-of-the-art machining centers, showcase our commitment to delivering high-quality components efficiently.

Learn how our meticulous design process, combined with our expertise in stamping and plating, offers unparalleled precision and cost-effectiveness.

News and insights

Everything about the market, Batten and Allen and the services we offer to give you the competitive edge.

3 min read

The Art and Science of Electroplating in Precision Manufacturing

Mar 18, 2024 by Batten & Allen

3 min read

Choosing the Right Material: A Comprehensive Guide for the Electronics Industry

Mar 4, 2024 by Batten & Allen

Tooling Reliability

Batten & Allen: In-house precision tooling and state-of-the-art toolroom expertise. Questions about our services? We're here to help.