Advanced Reel-to-Reel Electroplating for Enhanced Performance

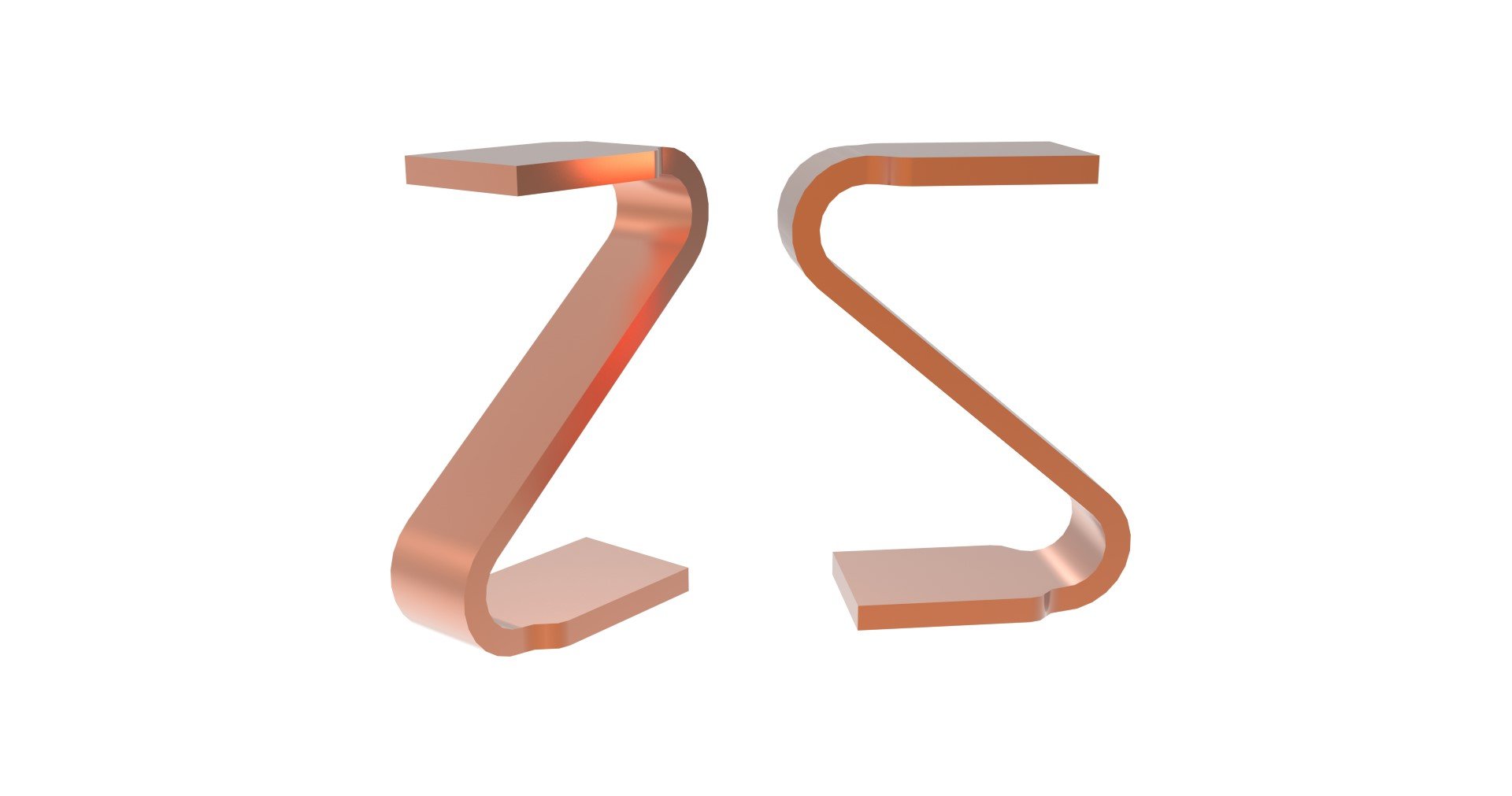

Continuous reel-to-reel production with plating fully integrated into our stamping process.

In-house plating optimised for durability, conductivity and corrosion resistance

At Batten & Allen, we enhance the finish of your components using high-quality, custom-designed reel-to-reel electroplating lines. Ranging from selective to precious metal plating, our multi-finish capabilities cater to a host of requirements across countless industries.

Our facility is home to eight in-house electroplating lines, capable of reel-to-reel plating of stamped components, as well as pre-plating of continuous coil materials for later stamping. This integrated approach allows us to deliver superior quality and rapid production turnaround.

With a policy of maximum self-sufficiency, our electroplating lines are designed and built on-site - allowing us to achieve the highest standards of quality and efficiency, which can be maintained under our own roof. The empowers us to deliver our services without unexpected delays, and to help you meet your own production deadlines at speed.

Expert Engineering Support

Our engineers are committed to helping you choose the best plating finish for your needs. Equipped with a fully operational process laboratory, we meticulously monitor and control plating solutions and thickness.

Our practices are designed to minimise waste and meet stringent customer and environmental standards, collectively contributing to a greener manufacturing process.

Tailored Solutions Across Market Sectors

We pride ourselves on our ability to serve diverse market sectors with components crafted from bespoke tooling, including:

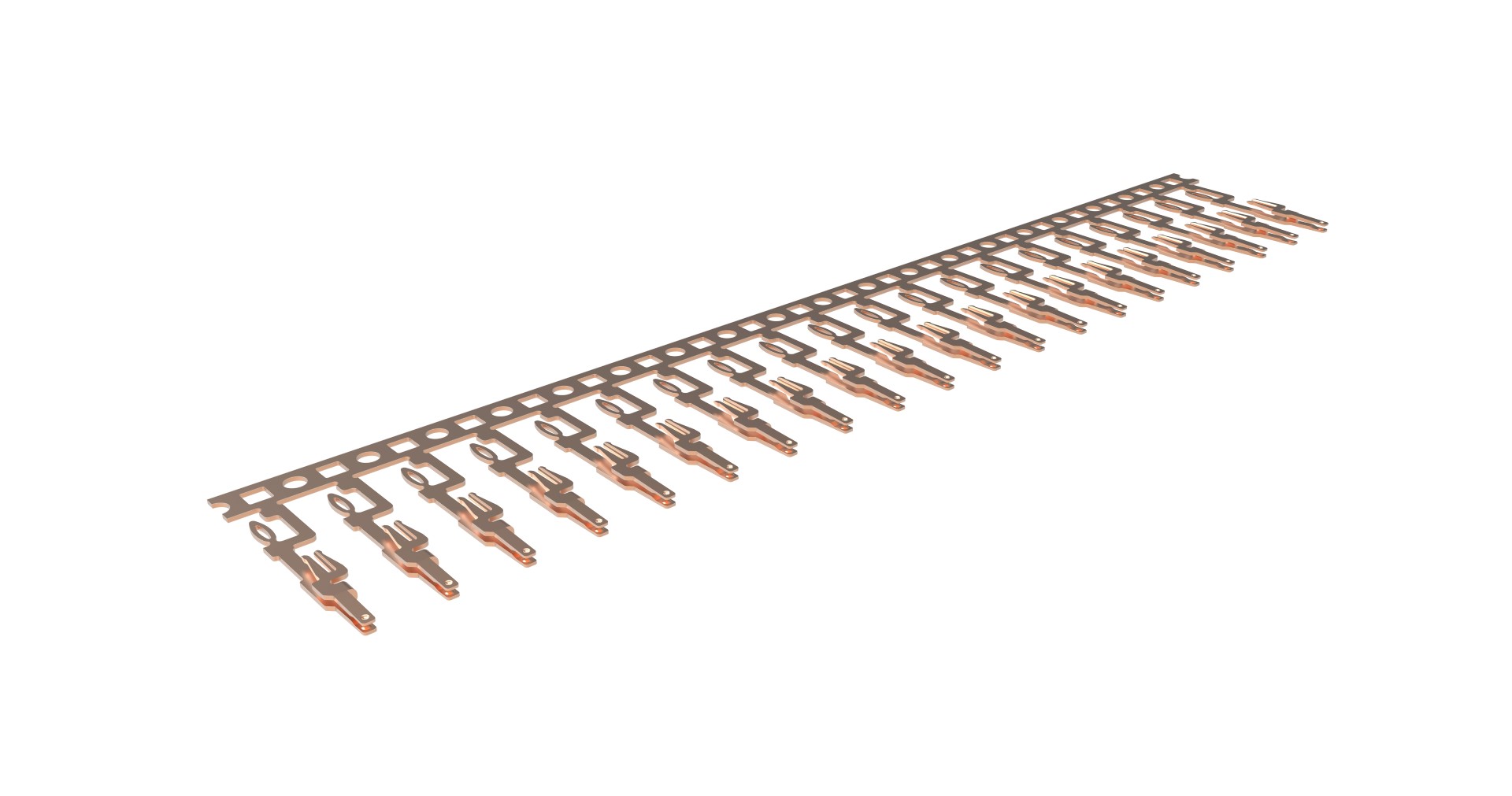

- Lead Frames. Created for the electronics market, our multi-impression fine tolerance lead frames are produced with up to 32 impressions. This capability allows us to offer millions of parts at a competitive price, with options for pre-plated, post, or selective plating to meet specific requirements. Explore our Lead Frames.

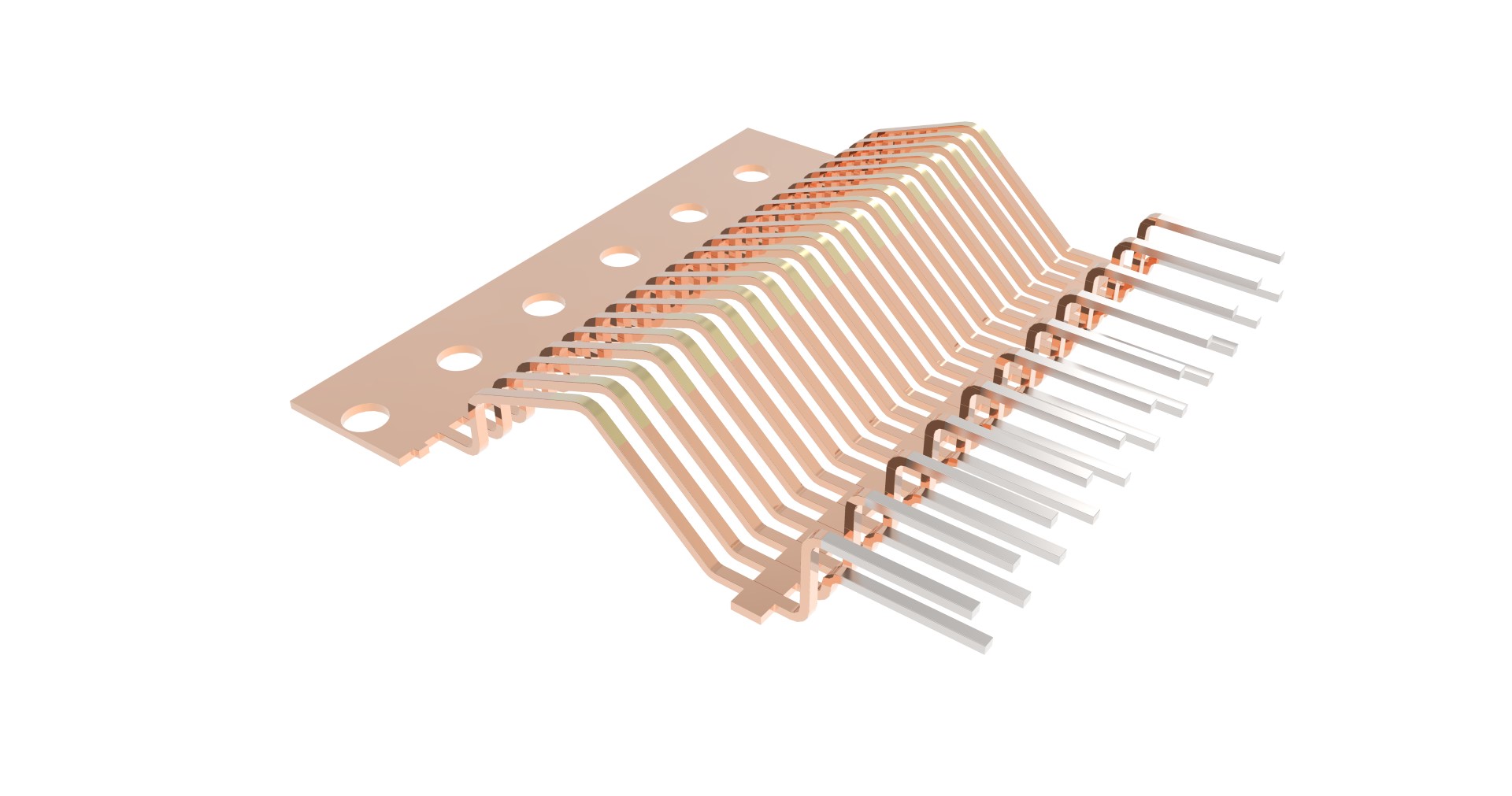

- Connectors. Our in-house design facility enables us to provide a varied selection of connectors tailored to all markets. Supported by our plating lines and comprehensive assembly tooling support, we deliver complete connector solutions.

- Press-Fit Pins. Recognised for our expertise in compliant pin components, we supply pins from standard or high-performance alloys in various thicknesses. Collaborating closely with our customers, we develop new designs to meet emerging challenges.

- IDCs. We manufacture fine-tolerance Insulation Displacement Connectors in a range of materials and plating finishes. Designed for close-pitch applications, these connectors are optimised for fast automated assembly with carrier bars.

Advanced Plating And Precision Stamping of Components

Discover the advantages of our new technology for your stamped components…

Find out moreThe Perfect Partnership

A partnership with Batten & Allen is underpinned by a shared ethos of precision, quality, and excellence. The perfect partner, is likely part of industries such as automotive, electronics, or aerospace, and shares a dedication to customised solutions. This partner values a transparent, and collaborative purchasing process, facilitating seamless communication and adherence to both compliance and high-quality standards.

Precision Plating

Batten & Allen's plating services are designed to meet the most exacting specification. This attention to detail in the plating process highlights a commitment to delivering high-quality finished products.

Customised Plating Solutions

Batten & Allen offer tailored plating solutions to suit the unique demands of every project. Our service accommodates a diverse range of industrial applications..

Quality Assurance

Upholding stringent quality control measures, Batten & Allen ensure that every plated component meets or exceeds industry standards. Our customers can trust the consistency and durability of the plated finishes, as every order is fully inspected for compliance and safety.

Hi-Tech Tooling

By harnessing cutting-edge technology, Batten & Allen enhance the efficiency and precision of their plating services. Their continual investment in modern equipment and processes underscores their pursuit of delivering the best quality components.

Cost-Efficiency

Through optimised operations and economies of scale, Batten & Allen offer cost-effective plating solutions without compromising on quality. Clients benefit from competitive pricing, ensuring value for money while retaining the high-quality standards they expect and deserve.

On Time, Every Time

Commitment to punctuality in delivering services enables Batten & Allen to meet strict deadlines. This offers peace of mind and a the confidence to entrust us with your order.

Case Study

Precision tooling excellence: from prototype to production

Dive into Batten & Allen's journey of mastering tooling design, ensuring reliability at every stage. Our in-house capabilities, from advanced wire erosion to state-of-the-art machining centers, showcase our commitment to delivering high-quality components efficiently.

Learn how our meticulous design process, combined with our expertise in stamping and plating, offers unparalleled precision and cost-effectiveness.

News and insights

Everything about the market, Batten & Allen and the services we offer to give you the competitive edge.

Seamless Manufacturing Solutions (Video)

Dec 9, 2024 by Batten & Allen

3 min read

Why Turnkey Solutions Are Essential to Manufacturing Success

Nov 26, 2024 by Batten & Allen

Expertise in Plating Reliability

From custom-designed reel to reel electroplating lines to serving diverse market sectors, Batten & Allen stands as a beacon of quality and innovation. Have specific requirements or queries? We're here to assist.

Talk to an expert

.jpg?width=1000&height=551&name=Custom%20Connectors%20(1).jpg)