Corrosion Resistance and Electroplating: What Design Engineers Need to Know

Introduction Among the top priorities for anyone in the business of manufacturing and design engineering are longevity and reliability.

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

3 min read

Batten & Allen Mar 18, 2024 8:16:46 AM

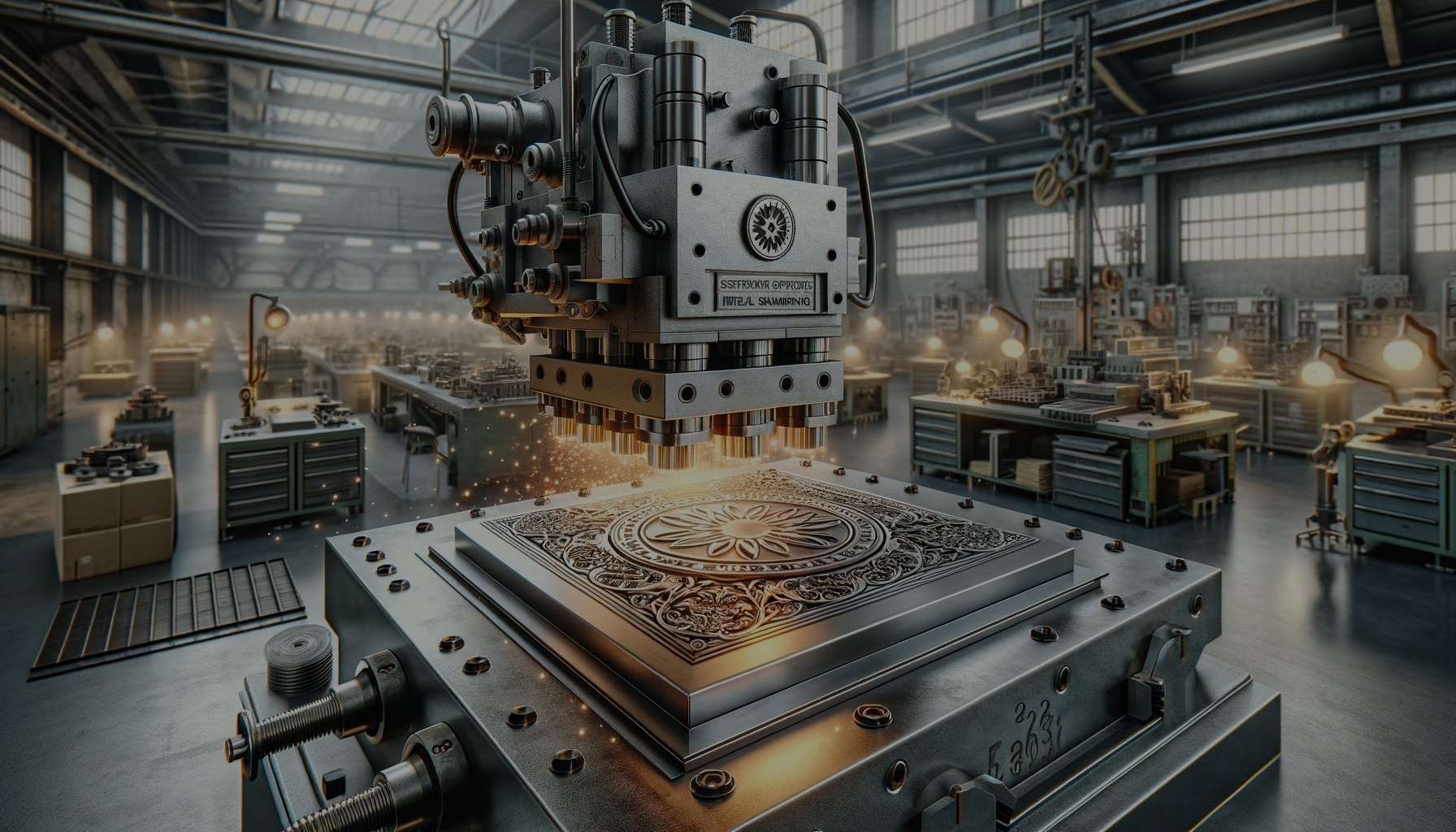

Precision manufacturing is an area of engineering where the boundaries of innovation and tradition are often blurred. This is a great description of the process of electroplating.

This method, rooted in ancient techniques yet still a crucial part in modern technological advancements, serves as a cornerstone in the development of high-performance, durable, and aesthetically pleasing metal components.

It's a practice that not only demands scientific precision but also an expert touch, exemplified by industry leaders like Batten & Allen.

Our commitment to pushing the frontiers of precision engineering shows just how important electroplating is in today's manufacturing environment.

Electroplating is a chemical process that uses electricity to deposit a thin layer of material onto a substrate, enhancing the substrate's properties without compromising its structural integrity.

This recipe of electrons and ions transforms the ordinary into the extraordinary, turning metals into “super metals” with enhanced corrosion resistance, improved wear properties and increased electrical conductivity. It can also improve the metal’s appearance.

The choice of plating material—be it gold for its conductivity and aesthetic, nickel for its durability, or copper for its electrical properties—depends entirely on the intended use.

Electroplating has its roots in the principles of electrochemistry, a science that studies the movement of electrons to create chemical change.

This process is carefully controlled through variables such as voltage, current density, electrolyte composition, and plating time. Each process is finely tuned to ensure the deposited layer meets exacting standards of thickness, adhesion, and uniformity.

Innovations in this field often emerge from an understanding of materials science, particularly in developing new electrolyte solutions that can offer improved efficiency or environmental benefits. For instance, advances in pulse plating technology allow for more precise control over the deposition process, leading to higher quality coatings with superior properties.

Despite its technical nature, electroplating remains every bit the art form. There is a real skill in preparing the substrate and designing the plating setup.

It’s a delicate operation which plays a critical role in achieving a perfect result.

This expertise comes from years of hands-on experience and an understanding of how different materials act together under different conditions. The aesthetic judgment of the technician, combined with scientific precision, ensures each piece not only performs at its best but also meets the highest standards of visual appeal.

Electroplating's versatility makes it invaluable across numerous sectors. In the aerospace industry, components are plated with metals like nickel or gold to withstand the harsh conditions of outer space or the corrosive environment of high-altitude flying.

The automotive sector relies on electroplating for parts that require durability and corrosion resistance, enhancing reliability and safety.

Electroplating is fundamental in the manufacture of printed circuit boards (PCBs), where copper plating ensures efficient electrical connectivity. The medical device industry benefits from electroplating through the creation of components that are both biocompatible and durable, crucial for life-saving equipment.

Electroplating is not without its challenges. Environmental concerns exist, particularly regarding the use of toxic chemicals and the generation of hazardous waste.

Industry leaders like Batten & Allen are at the forefront of developing greener alternatives and waste treatment solutions that mitigate environmental impact without compromising quality.

Technological advancements also address issues of precision and efficiency in the plating process. The development of new alloys and composite coatings opens up exciting possibilities for creating materials with tailored properties, suitable for even the most demanding of applications.

The future of electroplating in precision manufacturing is bright, driven by innovation and a commitment to excellence. New ideas, such as nanotechnology and advanced materials science, promise a new era of electroplating capabilities. These advancements are leading to even more efficient, environmentally friendly, and cost-effective processes, further expanding the applications of electroplating in precision manufacturing.

Companies like Batten & Allen continue to play a pivotal role in this area. Our dedication to pushing the boundaries of what's possible in electroplating not only enhances the quality and performance of manufactured components but also contributes to the sustainability and efficiency of manufacturing processes worldwide.

We live in exciting times, driven by advances in nanotechnology, material science, and environmental engineering. Innovations such as selective plating, where specific areas of a component are plated using precise application techniques, and the development of new alloy coatings with superior properties, are set to redefine the standards of performance and sustainability.

The continued evolution of electroplating techniques stands testament to B&As commitment to excellence and sustainability. By embracing both the art and science of electroplating, we aim to ensure the future of precision manufacturing is not just brighter but also greener and more efficient.

Introduction Among the top priorities for anyone in the business of manufacturing and design engineering are longevity and reliability.

Introduction In the fast-paced and ever-evolving electronics industry, the demand for precision and reliability in component manufacturing is a top...

Introduction In manufacturing, the ability to offer customised solutions is a critical requirement for innovation and success. This is especially...