Mastering Metal Stamping:

A Comprehensive Guide to Precision Manufacturing

Introduction

Understanding Precision Metal Stamping

Precision metal stamping is a manufacturing process that involves converting flat metal sheets into specific shapes that meet precise specifications. This process is achieved through a series of stamping operations, which may include one or more of the following techniques:

- Punching. This is where holes are created in the metal sheet or strip. The punch and die have corresponding shapes, allowing for the creation of holes in various shapes and sizes.

- Blanking. In blanking, parts are cut out of the metal sheet using a die. The blank is the piece of metal removed, which becomes the workpiece for further processing.

- Bending. Bending involves deforming the metal around a straight axis to create a fold, flange, or other shapes. This is done with specialist machinery that ensures the bend is precise and consistent.

- Forming. Similar to bending, forming involves shaping the metal but with more complex contours and not limited to linear folds. It can create three-dimensional shapes required for various components.

- Drawing. This is a process where the metal is stretched into a specific shape, usually a cavity or a deeper shape, by controlled material flow. Drawing is often used to create parts like pots and casings.

- Embossing. Embossing is used to create raised or recessed designs on the metal surface. It's a way to strengthen the material or add a decorative pattern.

- Coining. Coining involves compressing the metal with a die to create detailed impressions. The high pressure reshapes the metal within the die cavity, which can be used to create precise features.

Precision metal stamping is used to produce a wide range of products, from small components like electrical contacts and connectors to larger items like automotive parts. The process is favoured for its ability to produce large volumes of parts with high precision and repeatability, which is essential for maintaining the integrity of assembly processes in various industries.

The "precision" aspect refers to the tight tolerances and consistent quality that the stamping process can achieve. Tolerances - the allowable variations in the dimensions of a manufactured part - are critical in many applications where components must fit together exactly and function reliably over time.

Batten & Allen specialise in this precise manufacturing process, leveraging advanced technology and engineering expertise to produce parts that meet stringent quality standards. Their capabilities in precision metal stamping allow them to serve the demanding needs of the electronics industry, where components must often fit and function within the confines of increasingly complex devices.

Table of content

Understanding Precision Metal Stamping

The Role of Electroplating in Precision Metal Stamping

Benefits of Electroplating for Durability and Conductivity

The History & Evolution of Precision Metal Stamping

The Precision Metal Stamping Process

Stamping Operations: Blanking, Piercing, Forming, And Drawing

Commonly Used Metals and Their Properties

The Electroplating Process Explained

Types of Metal Finishes and Their Applications

Batten & Allen's Electroplating Capabilities

In-House Electroplating Facilities

Customisation Options for Various Industries

Quality and Compliance in Electroplating and Metal Stamping

Industry Standards for Electroplating and Metal Stamping

Environmental Considerations and Sustainability

Industries and Applications: Electronics Industry

Connectors and Semiconductor Components

Beyond Electronics: Diverse Applications

Automotive, Aerospace, and Telecommunications Sectors

Custom Solutions for SMEs Across Various Sectors

Design Engineering and Collaboration

Partnering with Design Engineers

Scaling Production with Precision

For Buyers and Purchasers: Navigating the Procurement Process

Understanding the Value of Quality in Procurement

Cost-Efficiency and Risk Management

Building a Supply Chain with Batten & Allen

Reliability and Consistency in Supply

Strategic Partnerships and Long-Term Collaborations

Competitive Advantages for Buyers

Streamlined Ordering and Delivery Processes

The Future of Precision Metal Stamping and Electroplating

Emerging Trends and Technologies

Electroplated Stamped Parts

Basics of Electroplating

Electroplating is a process that enhances the properties of metal components by coating them with a thin layer of a different metal, through an electrochemical reaction.

During this process, the parts to be plated are submerged in a solution containing the plating metal, which is then electrically charged to facilitate the transfer of metal ions onto the part's surface. This creates a bond between the two metals at a molecular level, resulting in a coating that can:

- Improve the part's resistance to corrosion.

- Increase its thickness.

- Enhance its overall strength and durability.

These qualities are paramount for our electroplated stamped parts, giving them the high-end quality reputation they deserve.

Benefits of Electroplating for Durability and Conductivity

Electroplating is critical in precision metal stamping for several reasons, including…

1. Increased Durability

Electroplating can significantly increase the lifespan of stamped metal parts by adding a layer of metal that resists corrosion, wear, and tear. For example, plating with nickel can create a barrier that protects the base metal from oxidising and corroding. This is particularly important in harsh environments where parts are exposed to moisture, chemicals, or extreme temperatures.

2. Enhanced Conductivity

For electrical components, conductivity is key. Electroplating with metals like gold or silver can improve a part's electrical conductivity, ensuring efficient and reliable performance in electrical applications. This is essential for components like connectors, switches, and contacts found in electronic devices.

3. Improved Solderability

Electroplating can also improve the ability of the part to be soldered, which is crucial in the electronics industry. Metals like tin are often used to plate parts to ensure a good solder joint.

4. Aesthetic Appeal

In addition to functional benefits, electroplating can also be used to improve the appearance and brightness of metal parts, which can be important for consumer-facing products.

5. Controlled Layer Thickness

Electroplating allows for precise control over the thickness of the plated layer, enabling manufacturers to ensure that parts meet exact specifications for both fit and function.

6. Selective Plating

It's possible to plate only specific areas of a component to provide conductivity or protection where it's most needed, conserving the more expensive plating material and reducing costs.

The benefits of electroplating have been pivotal in the evolution of precision metal stamping. This evolution is marked by significant technological advancements that have transformed the way metal components are manufactured.

The History & Evolution of Precision Metal Stamping

Early Methods of Metal Stamping

The history of metal stamping dates back to the early efforts of blacksmiths who used manual hammers to shape metals into desired forms. These early methods were labour-intensive and lacked the precision of modern techniques.

Over time, with the advent of the Industrial Revolution, manual labour was supplemented by steam-powered presses, which introduced the ability to mass-produce metal parts with improved consistency and efficiency.

As the demand for precision grew, especially with the rise of complex machinery and devices, so did the need for advancements in metal stamping technology. The development of mechanical presses in the late 19th and early 20th centuries allowed for the creation of more intricate parts with tighter tolerances. These machines used fixed dies and punches to shape metal sheets with each stroke of the press, a method that remains fundamental to stamping today.

Technological Advancements

The mid-20th century brought further innovation with the introduction of automated control systems, which enabled higher precision and repeatability.

The use of computers and digital technology in the latter part of the century revolutionised the field, giving rise to CNC (Computer Numerical Control) stamping machines. These machines allowed for the programming of complex and precise stamping operations, reducing the margin of error to a minimum and significantly increasing production rates.

In addition to mechanical and control upgrades, advancements in tooling materials and design have also played a crucial role. High-speed tool steels and carbide dies, for instance, have extended the life of stamping tools, allowing them to withstand the rigors of high-volume production without losing accuracy.

The transition into the 21st century has seen the incorporation of robotics, laser cutting, and 3D printing into the metal stamping process, further pushing the boundaries of what can be achieved. These technologies have enabled the production of parts with complex geometries that would have been impossible with earlier stamping methods. They also allow for rapid prototyping, which accelerates the development process and brings products to market faster.

Today, precision metal stamping is an integral component of manufacturing in a global economy, with continuous improvements in speed, precision, and versatility. Companies like Batten & Allen are at the forefront of these advancements, utilising state-of-the-art technology to meet the growing demands of industries that rely on high-quality stamped metal parts.

The Precision Metal Stamping Process

Building on the rich history and evolution of precision metal stamping, the process has become a sophisticated interplay of design, engineering, and meticulous execution.

Today's precision metal stamping process is a testament to the industry's progression, encompassing advanced design and engineering, precise tooling and die making, and a variety of stamping operations tailored to produce components with unparalleled accuracy.

Design and Engineering

The journey of a stamped metal part begins with design and engineering, where specialised software is used to create and simulate the desired part. This phase ensures that all specifications are met before any physical work begins, saving time and resources by identifying potential issues early on. Engineers consider material properties, intended use, and the complexities of design to ensure the final product will perform as required.

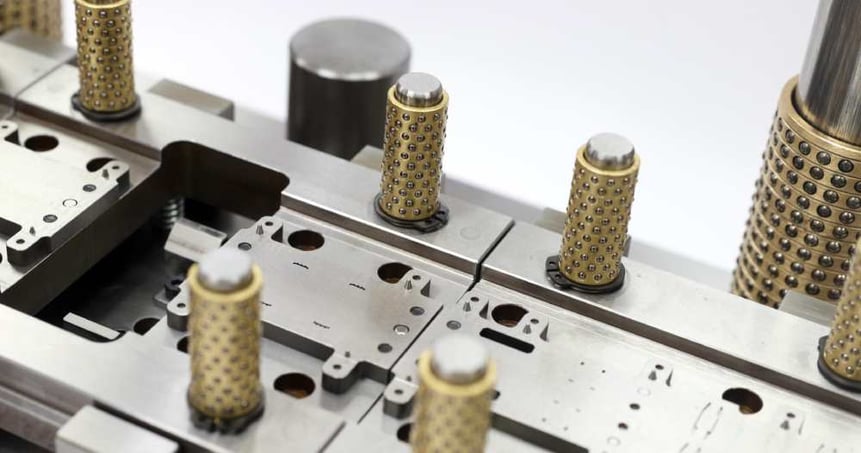

Tooling and Die Making

Tooling and die making are the next critical steps, where precision tools are crafted to match the part's specifications. Dies must be made with high precision to ensure that each stamped part is consistent with the original design. Batten & Allen, for instance, employs advanced tooling techniques, including modular design and wire erosion capability, to create tools that produce high-precision parts efficiently.

Stamping Operations: Blanking, Piercing, Forming, And Drawing

Stamping operations such as blanking, piercing, forming, and drawing are conducted with the tools we just discussed. Blanking cuts out the part from the metal sheet, piercing creates necessary holes or slots, forming shapes the metal into three-dimensional forms, and drawing extends the metal into complex shapes. Each of these operations requires precision machinery calibrated to exact specifications to ensure every part is a perfect replica of the last.

Quality Control and Assurance

In precision metal stamping, quality control and assurance are critical, encompassing a comprehensive regimen that begins with the scrutiny of raw materials and persists through meticulous in-process inspections and final product testing.

Utilising statistical process control to maintain consistency, and employing non-destructive testing methods for integrity verification, these practices ensure that each stamped part conforms to the exacting tolerances and finish quality required for their specific applications.

This relentless focus on quality not only fulfils the immediate specifications of customers but also feeds into a cycle of continuous improvement, enhancing the reliability and functionality of the parts in their end-use environments.

Materials in Metal Stamping

The selection of materials in metal stamping is a critical decision point that significantly affects the functionality and performance of the finished parts. Various metals are chosen based on their unique properties to match the specific demands of different applications.

Commonly Used Metals and Their Properties

Metals commonly used in stamping include steel, aluminium, copper, brass, and specialty alloys.

Steel, known for its strength and durability, is widely used in automotive and construction industries. It can be further processed into stainless steel, which offers corrosion resistance for medical and food-related applications.

Aluminium is favoured for its lightweight and corrosion-resistant characteristics, making it suitable for aerospace and consumer electronics where weight is a concern.

Copper and its alloys, like brass, are chosen for their excellent electrical conductivity and are commonly used in electrical components and connectors.

Specialty alloys may be used when a combination of properties, such as high strength, temperature resistance, or magnetic permeability, is required.

Material Selection Process

The material selection process in metal stamping involves analysing the part's required mechanical properties, environmental exposure, expected lifespan, and electrical requirements.

Manufacturers must consider the metal's formability, strength, weight, and cost-effectiveness for large-scale production. The compatibility of the metal with the intended plating process is also a crucial factor, as some metals adhere to plating better than others, influencing the durability and efficacy of the electroplating finish.

Expertise in Material Science

An understanding of material science is paramount in selecting the appropriate metal for a stamping project. Expertise in this area allows for the prediction of how different metals will behave under various manufacturing processes, including stamping and plating.

Knowledge of metallurgy helps in optimising the tool design and stamping parameters to reduce wear on the dies and increase the efficiency of the stamping process.

Manufacturers with a deep understanding of material science can provide valuable guidance during the design phase, suggesting modifications that can enhance the part's performance while keeping production costs in check. They can also help in troubleshooting issues related to material behaviour, such as unexpected brittleness or warping during the stamping process, ensuring that the final products meet the quality and performance criteria set by the client.

The Electroplating Process Explained

Electroplating involves the deposition of a metal onto a conductive surface.

The object to be plated, known as the substrate, is immersed in an electrolyte solution containing one or more metal salts. The substrate acts as the cathode of an electrical circuit, while the anode is made of the plating metal.

When an electric current is passed through the circuit, metal ions in the solution are reduced and bond to the substrate, forming a coherent metal coating. The thickness of the plating is controlled by the current and the time the substrate is left in the solution.

Types of Metal Finishes and Their Applications

Different metals are used for plating to provide various desired characteristics to the substrate. These metals include…

- Gold Plating. Used for its excellent conductivity and resistance to corrosion, ideal for high-performance electronic connectors and PCBs.

- Silver Plating. Offers superior thermal and electrical conductivity, used in areas where high-frequency performance is required, such as in satellite communications and aerospace components.

- Nickel Plating. Known for its toughness and resistance to corrosion, it is commonly applied to parts that require durability, such as in the automotive and industrial sectors.

- Chrome Plating. Provides a high gloss finish that resists tarnishing and wear, it’s often used for decorative purposes as well as functional applications like on automotive trim and plumbing fixtures.

- Tin Plating. Exhibits excellent solderability and is used to facilitate soldering in electronic components, also provides corrosion resistance and is non-toxic.

- Zinc Plating: Offers excellent rust prevention, making it a go-to for protective coatings in hardware, military, and aerospace industries.

The selection of the type of metal finish is dictated by the application's specific requirements, including environmental exposure, electrical demands, wear conditions, and aesthetic preferences.

Each finish not only extends the functionality and service life of the component but can also contribute to its visual appeal. The process of choosing the right electroplating finish is a careful balance between performance specifications and cost-efficiency.

Batten & Allen's Electroplating Capabilities

Batten & Allen's robust electroplating capabilities are a testament to their dedication to delivering comprehensive in-house solutions.

Their state-of-the-art facility is equipped with eight specialised electroplating lines, including a £1.25 million investment in advanced reel-to-reel technology. This setup not only underscores their commitment to maintaining control over the electroplating process but also demonstrates their ability to provide high-quality, consistent finishes across a vast production scale.

With the capacity to pre-plate continuous coil material and plate stamped components reel to reel, they ensure efficiency and precision in every run.

In-House Electroplating Facilities

The in-house electroplating facilities at Batten & Allen represent a significant stride towards maximum self-sufficiency.

By designing and constructing their own high-speed plating lines, they have set themselves apart in the ability to rapidly produce and iterate high-quality plating for various components.

Their engineers' direct involvement in the plating process, supported by a fully equipped process laboratory, allows for meticulous control over the plating solutions and thickness, aligning with both customer specifications and environmental regulations.

Customisation Options for Various Industries

Batten & Allen's expertise in material science shines in their customisation options, which cater to the nuanced needs of diverse industries. They offer a spectrum of electroplating services tailored for electronics, automotive, medical, and industrial applications, ensuring that each sector receives components manufactured to exact standards.

Their ability to produce multi-impression fine-tolerance lead frames, connectors, and other precision parts with pre-plated, post-plated, or selective plating options allows them to serve market sectors with high efficiency and low unit costs, providing a complete solution from design to final product.

Quality and Compliance in Electroplating and Metal Stamping

In the electroplating and metal stamping industry, adherence to quality and compliance standards is paramount to ensure the production of safe, reliable, and superior-quality products.

Manufacturers across the sector are governed by a complex set of international standards, including ISO 9001 for quality management systems, ISO 14001 for environmental management, and ISO/TS 16949 for the automotive sector, which specify requirements for consistent product quality and regulatory compliance.

Industry Standards for Electroplating and Metal Stamping

The industry standards, such as those set by the International Organization for Standardization (ISO), provide a framework for best practices in manufacturing. These standards help companies establish a systematic approach to managing their processes and are critical for ensuring product quality.

For instance, ISO 9001 certification is a widely recognised standard that demands a quality management system to guide and control manufacturing operations effectively. This certification requires manufacturers to undergo rigorous evaluation processes to demonstrate their commitment to product quality, customer satisfaction, and continuous improvement.

Environmental Considerations and Sustainability

Environmental sustainability is a significant concern in the metal stamping and electroplating industry. Standards like ISO 14001 encourage organisations to minimise harmful effects on the environment caused by their activities and to achieve continual improvement of their environmental performance. This involves careful management of chemical use in electroplating, efficient waste management, and the adoption of recycling practices.

By following these guidelines, manufacturers contribute to a more sustainable manufacturing cycle and demonstrate corporate responsibility. Compliance with such environmental standards is not only ethically important but also serves to enhance the marketability of products in an eco-conscious consumer market.

Transitioning from the focus on environmental considerations and sustainability, it's important to recognise how these principles are applied in specific industries. The electronics industry, in particular, stands out as a significant area where precision metal stamping and electroplating play crucial roles.

Connectors and Semiconductor Components

In the realm of electronics, connectors and semiconductor components are critical for ensuring the efficient and reliable operation of electronic devices. Connectors, which facilitate electrical connections between different parts of a device, require precise manufacturing to ensure consistent performance.

Similarly, semiconductor components, which form the backbone of electronic circuits, demand high precision in their construction. Metal stamping and electroplating play vital roles in creating these components, offering the precision, durability, and conductivity needed for the electronics industry.

Away from the specifics of the electronics industry, it becomes evident that the expertise in precision metal stamping and electroplating extends far beyond just one sector. The versatility of these manufacturing techniques is showcased in their application across a diverse range of industries, each with its unique requirements and challenges.

Beyond Electronics: Diverse Applications

While the electronics industry significantly benefits from precision metal stamping and electroplating, these manufacturing techniques are equally vital across a variety of other sectors. Their adaptability allows for customisation to meet the specific needs of different industries, highlighting the broad impact and importance of precision metal stamping and electroplating in modern manufacturing.

Automotive, Aerospace, and Telecommunications Sectors

In the automotive industry, precision metal stamping and electroplating are indispensable for producing a range of durable and reliable components. These include connectors, sensors, and various engine parts, all of which are essential for the functionality and safety of vehicles.

The aerospace sector, known for its stringent quality and safety standards, relies heavily on these processes. Precision metal stamping and electroplating are used to create critical components for aircraft and spacecraft, where the highest levels of precision and strength are required. These components often include structural elements, engine parts, and electrical systems, all of which must withstand extreme conditions and stresses.

In the telecommunications sector, precision metal stamping and electroplating play a crucial role in manufacturing components for communication devices and infrastructure. This includes components for mobile devices, satellite communications, and network hardware. The precision and conductivity achieved through these processes are essential for ensuring reliable and high-speed communication, which is the backbone of the modern digital world.

Each of these sectors demonstrates the versatility and necessity of precision metal stamping and electroplating in creating components that meet the highest standards of quality, durability, and performance.

Custom Solutions for SMEs Across Various Sectors

Small and medium-sized enterprises (SMEs) across various sectors also benefit from the custom solutions provided by precision metal stamping and electroplating services.

These manufacturing techniques offer SMEs the flexibility to produce specialist components tailored to their specific needs, whether it's for niche markets or innovative new products.

By providing access to high-quality, custom-manufactured components, precision metal stamping and electroplating play a pivotal role in supporting the growth and diversification of SMEs in a wealth of industries.

Moving from the discussion on custom solutions for SMEs, it's crucial to delve into the collaborative aspect of manufacturing, particularly in the realm of design engineering. This collaboration is key to developing effective, innovative solutions that meet the specific needs of diverse industries.

Design Engineering and Collaboration

The intersection of design engineering and manufacturing is a dynamic space where creativity meets practicality. In this realm, the collaboration between design engineers and manufacturers is essential for translating innovative concepts into tangible, functional products.

This partnership is especially critical in industries where precision and customisation are paramount, as it ensures that the final products not only meet but exceed the expectations and requirements of the end-users.

Partnering with Design Engineers

Partnering with design engineers involves a synergistic relationship where the expertise of both parties is leveraged to achieve optimal outcomes.

Manufacturers bring their practical knowledge of materials, processes, and production constraints, while design engineers contribute their vision, innovation, and technical design skills. This partnership is crucial in navigating the challenges of product development, from conceptualisation to final production, ensuring that each step of the process is aligned with the project's goals and specifications.

Co-Development Processes

Co-development processes represent the epitome of this collaborative effort, where manufacturers and design engineers work hand-in-hand throughout the product development lifecycle.

This approach allows for continuous feedback and iteration, ensuring that the design is feasible from a manufacturing perspective and that the manufacturing process is tailored to realise the design effectively.

Co-development fosters a deeper understanding of the project's objectives and challenges, leading to more innovative solutions, efficient production, and ultimately, higher-quality products. This collaborative approach is particularly beneficial in sectors where cutting-edge innovation and precision are crucial, such as in advanced electronics, medical devices, and aerospace engineering.

Transitioning from the co-development processes, where design engineers and manufacturers collaborate closely, the journey of bringing a product from concept to reality involves several critical stages. This journey is characterised by meticulous prototyping, rigorous testing, and the eventual scaling of production, all while maintaining the highest standards of precision and quality.

From Concept to Reality

The transformation of a concept into a tangible product is a complex and multifaceted process. It begins with an idea or a design, which then undergoes various stages of development and refinement.

This journey is not just about the creation of a physical product but also about ensuring that the product meets all the functional, aesthetic, and quality requirements set forth at the concept stage.

Prototyping and Testing

Prototyping is an essential step in the product development process. It involves creating a preliminary model of the product to test its feasibility, functionality, and design. This stage allows manufacturers and designers to identify potential issues and make necessary adjustments before full-scale production.

Testing, both during and after the prototyping phase, is crucial to validate the product's performance under various conditions and to ensure it meets all safety, quality, and regulatory standards. Rigorous testing helps in fine-tuning the product, ensuring that it is ready for the market.

Scaling Production with Precision

Once a product has successfully passed through the prototyping and testing phases, the next challenge is scaling production. This stage involves transitioning from a prototype to mass production while maintaining the precision and quality achieved in the prototype.

Scaling production requires careful planning and execution, ensuring that each unit produced replicates the quality and specifications of the prototype. This process often involves optimising manufacturing techniques, streamlining operations, and ensuring quality control throughout the production process. The ability to scale production effectively is crucial for meeting market demand and achieving commercial success.

As we pivot from the topic of scaling production with precision, it's important to address another crucial aspect of the manufacturing cycle: the procurement process. For buyers and purchasers, navigating this process effectively is key to ensuring that the precision and quality achieved in production translate into value and efficiency in procurement.

For Buyers and Purchasers: Navigating the Procurement Process

The procurement process is a critical component of the manufacturing cycle, especially for buyers and purchasers in industries where precision and quality are non-negotiable. It involves more than just acquiring the necessary components; buyers must make informed decisions that balance cost, quality, and supply chain reliability.

Effective navigation of this process is essential for maintaining the integrity of the final product and the efficiency of the production process.

Understanding the Value of Quality in Procurement

In procurement, understanding the value of quality is crucial. This means recognising that the lowest cost option is not always the most cost-effective in the long run.

High-quality components may come with a higher upfront cost, but they can significantly reduce the likelihood of future failures, downtime, and maintenance costs.

For buyers and purchasers, this understanding is critical in making decisions that ensure the longevity and reliability of the products they are sourcing. Investing in quality can lead to better overall value, customer satisfaction, and a stronger reputation for the end product.

Cost-Efficiency and Risk Management

Cost-efficiency in procurement requires an understanding the total cost of ownership, which includes factors like lifespan, reliability, and maintenance requirements.

Effective risk management in procurement involves assessing potential supply chain disruptions, evaluating the reliability of suppliers, and ensuring that there are contingency plans in place. This approach helps in mitigating risks associated with delays, quality issues, or supply shortages.

By focusing on both cost-efficiency and risk management, buyers and purchasers can make strategic decisions that optimize their procurement process, ensuring a steady supply of high-quality components necessary for successful production.

Shifting from the crucial aspects of cost-efficiency and risk management in procurement, it's essential to consider how building a robust supply chain can further enhance these elements. When it comes to establishing a reliable and efficient supply chain, partnering with a company like Batten & Allen can offer significant advantages.

Their commitment to reliability, strategic partnerships, and streamlined processes aligns perfectly with the needs of buyers seeking competitive advantages in their procurement strategies.

Building a Supply Chain with Batten & Allen

Building a supply chain with Batten & Allen means entering into a relationship that is built on trust, reliability, and mutual benefit. Their experience and expertise in precision metal stamping and electroplating make them an ideal partner for companies looking to strengthen their supply chain with high-quality components.

Reliability and Consistency in Supply

One of the key strengths of Batten & Allen is their ability to provide reliability and consistency in supply. This is crucial for buyers who need to ensure that their production lines are always operational, and that product quality remains high.

Batten & Allen's commitment to maintaining a steady supply of components is underpinned by self-sufficiency, including – for example - the design and build of in-house high-speed electroplating lines. Coupled with their stringent quality control measures, buyers can depend on Batten & Allen for consistent product quality and timely deliveries – even when component batches run into millions of units.

Strategic Partnerships and Long-Term Collaborations

Batten & Allen values strategic partnerships and long-term collaborations with their clients.

By working closely with buyers, they gain a deep understanding of their specific needs and challenges. This collaborative approach allows for the development of tailored solutions and the alignment of production schedules and logistics to meet the unique demands of each buyer, fostering a partnership that contributes to mutual growth and success.

By working with OEMs from the earliest stages of product design and development, Batten & Allen is ideally positioned to deliver a complete engineering solution.

Competitive Advantages for Buyers

Batten & Allen’s expertise in precision manufacturing not only ensures high-quality components but also provides buyers with the edge they need in a competitive market.

By leveraging Batten & Allen's manufacturing capabilities and technological advancements, buyers can enhance their product offerings, improve their market position, and achieve greater customer satisfaction.

Streamlined Ordering and Delivery Processes

Batten & Allen also places a strong emphasis on streamlined ordering and delivery processes, making it easier for buyers to manage their inventory and logistics. Their efficient order processing, coupled with reliable delivery schedules, ensures that buyers can reduce their lead times and manage their stock levels more effectively.

This efficiency in the supply chain process not only saves time but also reduces the overall cost of procurement, contributing to a smoother, more efficient production cycle.

As we conclude our exploration of the precision metal stamping and electroplating industry, it's important to look ahead. The future of this industry is not just shaped by current practices but also by emerging trends and technologies that promise to redefine manufacturing standards and capabilities.

The Future of Precision Metal Stamping and Electroplating

The future of precision metal stamping and electroplating is poised at an exciting juncture, with advancements in technology and evolving industry demands driving significant changes. As we move forward, the industry is expected to continue its trajectory of innovation and efficiency, adapting to new challenges and opportunities.

Emerging Trends and Technologies

Emerging trends and technologies in precision metal stamping and electroplating are set to revolutionise the way manufacturers operate.

Advancements in automation, AI, and machine learning are expected to enhance precision, speed, and flexibility in manufacturing processes. Additionally, the growing emphasis on sustainability is driving the development of eco-friendly materials and processes.

The integration of IoT (Internet of Things) in manufacturing is also anticipated to improve real-time monitoring and quality control, leading to smarter, more connected production environments.

Batten & Allen's Ongoing Commitment to Excellence

Batten & Allen's ongoing commitment to excellence positions them well to embrace these future trends and technologies.

Their dedication to innovation, quality, and customer satisfaction ensures that they will continue to be at the forefront of the industry. As they adapt to emerging technologies and evolving market needs, Batten & Allen is poised to not only meet but exceed the expectations of their clients, reinforcing their role as a leader in the precision metal stamping and electroplating industry.

Explore our stamping capabilities.

Getting Started with Batten & Allen

Whether you're looking for a long-term partnership or need assistance with a specific project, Batten & Allen's approachable and professional team is ready to guide you through the process.

Contact us now!