Precision Stamping Reliability: The Batten & Allen Promise

In the intricate world of metal stamping, precision and reliability are more than goals. They’re absolute necessities.

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

2 min read

Batten & Allen Aug 22, 2024 5:12:11 PM

The ability to estimate project costs is a fundamental part of the manufacturing process. Whether you're developing cutting-edge consumer electronics or intricate components for industrial applications, understanding the financial implications of your production processes can make or break the project.

This is where a project estimation calculator comes into its own. Designed to provide a clear and concise overview of potential costs, these calculators are essential for manufacturers working with high-precision parts.

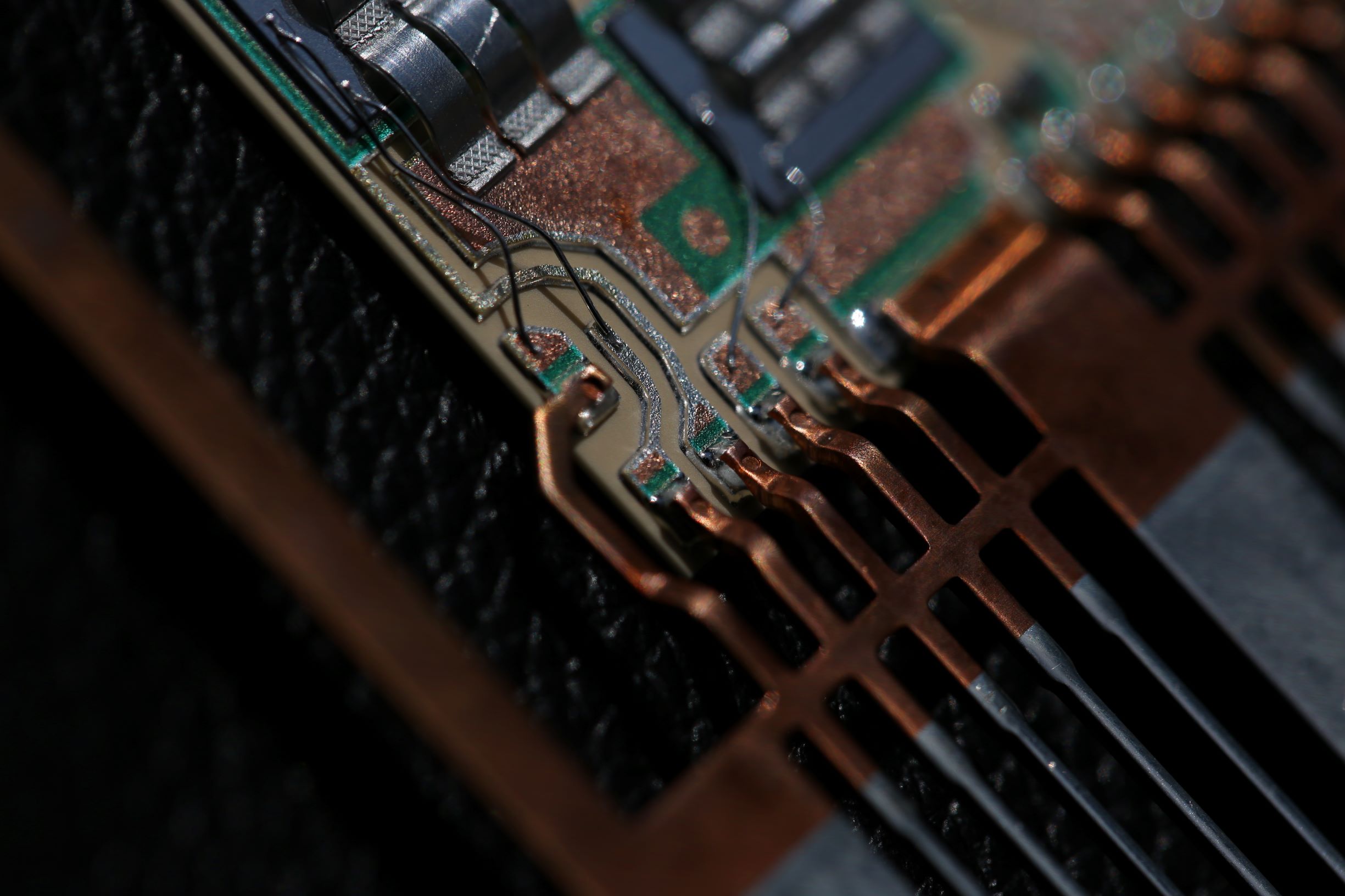

Electronics manufacturing is defined by its high level of precision. Every component, from microchips to connectors, must meet exact specifications to ensure the final product functions exactly as it should. A project estimation calculator allows manufacturers to forecast approximate costs associated with producing high-precision parts.

This is not merely about the price of raw materials; it also includes tooling costs, labour, potential wastage, and other expenses that might arise during the production process. By providing a breakdown of these costs, a project estimation calculator lets manufacturers make informed decisions.

Streamlining the Quotation Process

Streamlining the Quotation ProcessOne significant benefit of using a project estimation calculator is the ability to streamline the quotation process. In the traditional model, obtaining a quote for high-precision parts can take time. It often involves back-and-forth communication between manufacturer and supplier, detailed discussions, and the need for expert input to ensure all aspects of the project are considered.

With a project estimation calculator, this process is simplified. Manufacturers can input details into the calculator, such as material type, part dimensions, and production volume, and instantly receive a rough estimate of the project costs. In the case of Batten&Allen, this will later be confirmed by a member of our sales team.

Without a clear understanding of project costs, manufacturers risk underestimating expenses, which can lead to overspending and reduced profitability. Conversely, overestimating costs can result in higher prices, making it more difficult to remain competitive.

A project estimation calculator helps mitigate these risks by providing a realistic cost estimate based on specific project parameters. This is particularly important in the production of high-precision parts, where small deviations in material quality, production methods, or tolerances can have significant cost implications.

Beyond just cost estimation, a project estimation calculator also plays a part in overall project planning and decision-making. By providing an approximate view of potential costs, manufacturers can assess the feasibility of different production methods, material choices, and design alternatives. This allows them to make strategic decisions that align with their finances and production capabilities.

For example, if a particular material is found to be too expensive, a manufacturer might explore alternative materials or production techniques that offer a better balance between cost and performance.

Similarly, understanding the cost implications of different production volumes can help manufacturers determine the most cost-effective scale for their operations. In this way, a project estimation calculator becomes a powerful tool for strategic planning, helping manufacturers optimise their processes and achieve better outcomes.

Delays and cost overruns can have serious consequences. Not only do they impact the financial performance of a project, but they can also damage relationships with clients and suppliers. A project estimation calculator helps reduce these risks by providing a rough estimate of potential costs and timelines from the start.

Additionally, by having a clear understanding of the cost structure, manufacturers can more effectively plan their production schedules, ensuring that resources are allocated efficiently and that the project stays on track.

Supporting Competitive Advantage in the Market

Supporting Competitive Advantage in the MarketLast but not least, a project estimation calculator can provide manufacturers with a competitive edge in the market. In an industry where margins are often tight, the ability to estimate and control costs is a significant advantage. Clients are more likely to choose a manufacturer provides transparent cost estimates, as this reduces the risk of unforeseen expenses.

A project estimation calculator is an indispensable tool for manufacturers working with high-precision components, offering numerous benefits from streamlining the quotation process to enhancing project planning and decision-making.

In the intricate world of metal stamping, precision and reliability are more than goals. They’re absolute necessities.

Lead frames are one of the foundations behind electronic components and ensuring their reliability and quality is essential for any component. What...

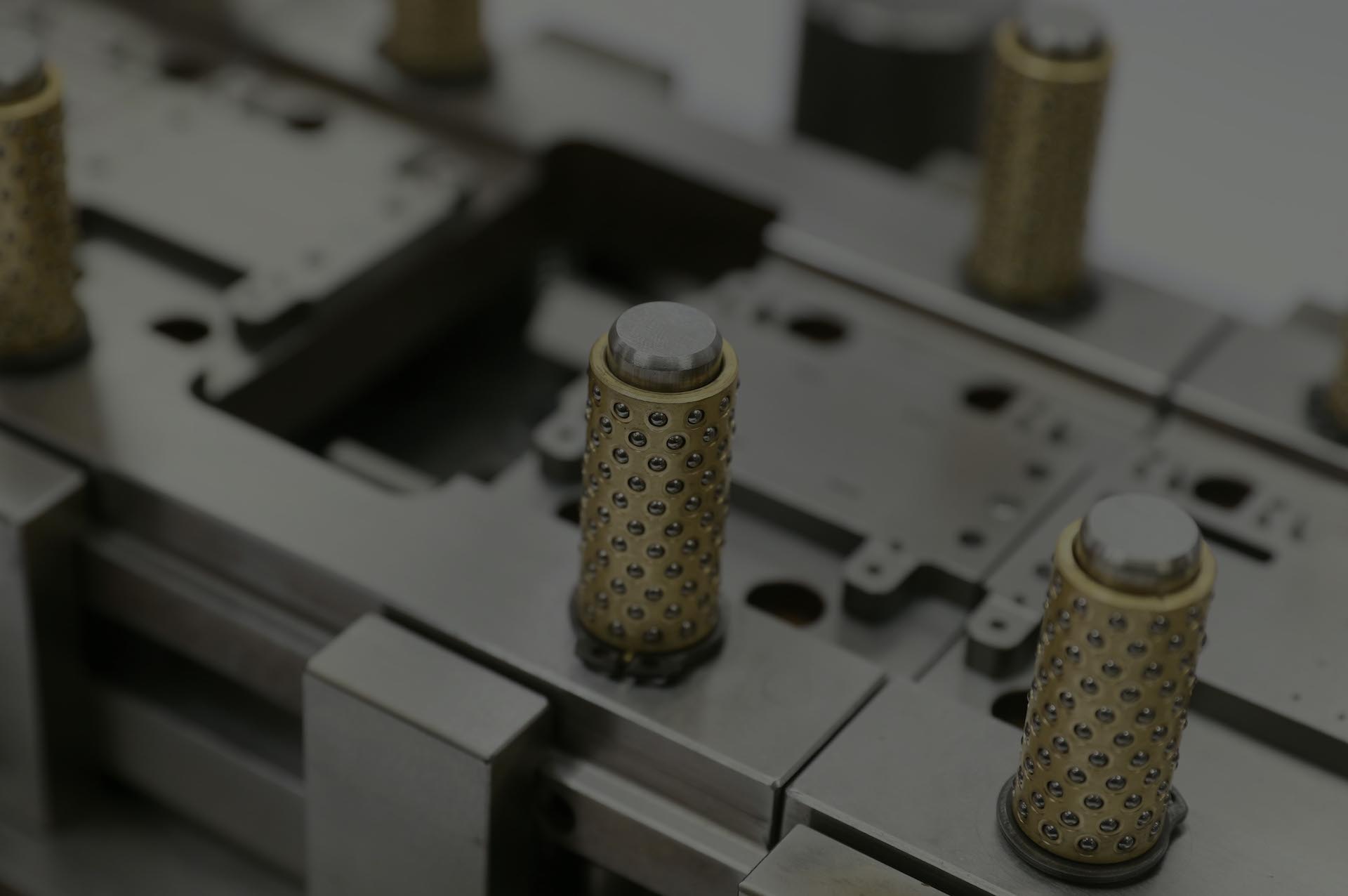

Built to last, our high accuracy, precision tooling is all designed and built in house. With a fully equipped toolroom we manufacture and design...