Precision Stamping Reliability: The Batten & Allen Promise

In the intricate world of metal stamping, precision and reliability are more than goals. They’re absolute necessities.

Brands are choosing us to partner with them to bring innovate products to market quickly and cost effectively.

Working on a Prototype and need expert input, why not get in touch and talk with our experts.

2 min read

Batten & Allen Feb 12, 2024 11:41:34 AM

In the precision-demanding world of metal stamping, achieving high-quality outcomes is a complex endeavour that requires a meticulous approach. Batten & Allen, a leader in the industry, has developed a comprehensive strategy to ensure excellence in every stamped product.

Here, we’ll explore the key aspects of Batten & Allen's approach to achieving and maintaining high-quality stamping outcomes.

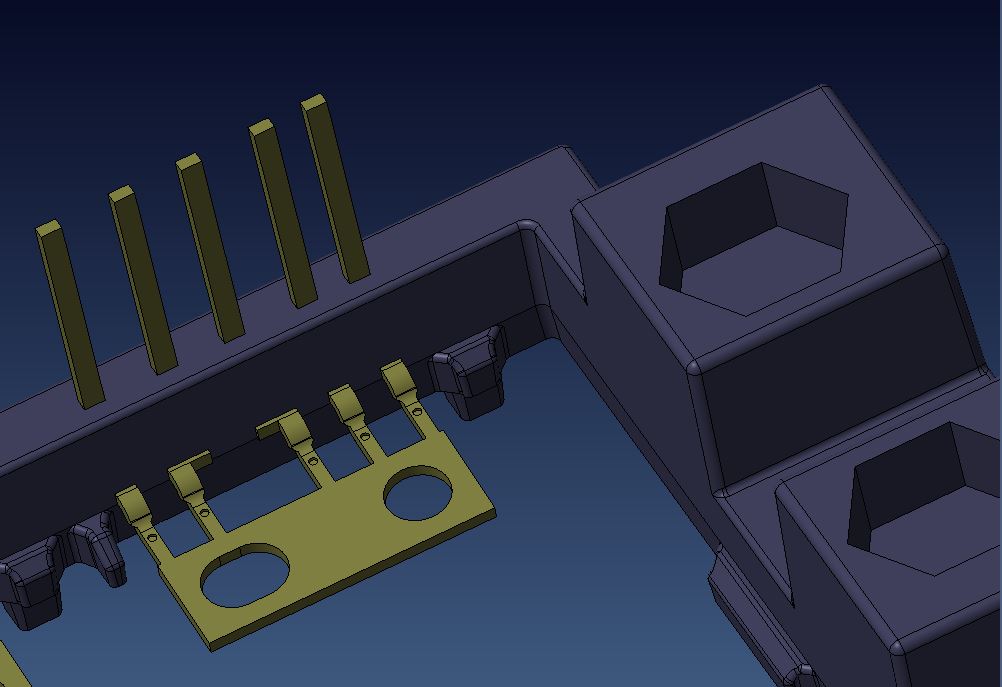

Batten & Allen’s commitment to quality begins at the design stage. Utilising advanced CAD and simulation tools, the company meticulously plans each stamping project, ensuring that potential issues are addressed before production begins.

This proactive approach in design significantly reduces the likelihood of defects and enhances the efficiency of the stamping process.

A key differentiator in Batten & Allen’s approach is their expertise in material selection.

Understanding that each project has unique requirements, they carefully choose materials that offer the best combination of strength, durability, and compatibility with the intended application. This material mastery is crucial in ensuring the quality and longevity of the stamped products.

Batten & Allen stands out for its ability to optimise stamping processes for maximum efficiency and quality.

By employing lean manufacturing principles, the company streamlines its operations, reducing waste and enhancing the precision of its stamping processes. This optimisation not only improves quality but also ensures timely delivery of products.

What sets Batten & Allen apart is their in-process quality assurance. Unlike traditional approaches that focus on end-product inspection, they monitor quality at every stage of the process.

This vigilant approach includes real-time monitoring of stamping parameters and intermediate inspections, ensuring that any deviations are corrected promptly.

Batten & Allen’s commitment to quality extends beyond the stamping press. Post-production analysis is a critical component of their approach.

Each project undergoes a thorough review to identify areas for improvement. This feedback loop is integral to their continuous improvement philosophy, driving enhancements in future projects.

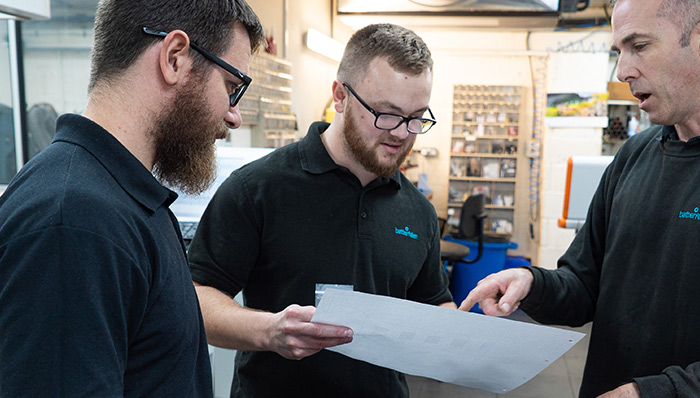

Batten & Allen take pride in fostering collaborative relationships with clients. By engaging them throughout the stamping process, final products can align perfectly with expectations.

This collaborative approach allows for customisation and adaptability, key factors in achieving client satisfaction.

Sustainability is woven into Batten & Allen’s approach to quality. The company recognises that sustainable practices not only benefit the environment but also contribute to the overall quality of their stamping processes.

From eco-friendly material choices to energy-efficient operations, their sustainable practices are a testament to their holistic approach to quality.

Batten & Allen’s approach to ensuring high-quality stamping outcomes is a blend of meticulous design, material expertise, process optimisation, vigilant quality assurance, and post-production analysis.

Their collaborative client relationships and commitment to sustainability further elevate their status as a leader in the metal stamping industry. It is this multifaceted approach that enables Batten & Allen to consistently deliver products that embody excellence and meet the evolving needs of their clients.

Find out more about delivering consistent stamping quality here.

In the intricate world of metal stamping, precision and reliability are more than goals. They’re absolute necessities.

When sourcing a new precision stamped component, both the stamping process and new tool design are key to ensuring production of a highly consistent,...

Achieving reliability in metal stamping is a complex challenge that industry leaders tackle through a combination of best practices, technological...